MECS has been the industry leader in the design and construction of sulfuric acid plants for over 75 years. With over 800 plants built in 56 countries around the world, our ability to understand the overall requirements of plant operation gives us a unique advantage in designing equipment to meet your specific needs.

In 1981, North Atlantic Technologies, Inc. introduced the Open Channel Air Preheater (OCAP), recuperative plate type heat exchanger. This unit’s design as a static device with no moving parts or working fluids makes it ideal for most gas to gas heat exchanger applications.

MECS has recently expanded our portfolio to include the Open Channel Air Preheater (OCAP) formerly offered by North Atlantic Technologies.

MECS has recently expanded our portfolio to include the Open Channel Air Preheater (OCAP) formerly offered by North Atlantic Technologies.

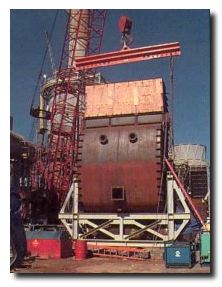

The OCAP is modular and custom designed for each application. The OCAP is very compact and available in both cross flow and counter flow configurations to fit the plot size in most retrofit installations.

This modular design offers the most flexible and efficient flow arrangements. It also offers significant improvements in design and operational flexibility, including the freedom to select appropriate materials of construction for each heat transfer zone.

![]()

OCAP units are durable and well suited for a variety of difficult applications:

|

|

OCAP units offer a unique opportunity to optimize the materials. By selecting multiple blocks in series, the designer can specify the appropriate metallurgy for each block: the cold block with stainless steel plates, the intermediate block with carbon steel plates, and the hot block with stainless steel plates.

Pressure and flow requirements can be addressed by changing module configuration or adding blocks in parallel or series.

The free floating nature of the plate pack along with the non-welded design creates minimal stress build up. The differential expansion problems typical of certain shell and tube designs are considerably lower in these units.

The free floating nature of the plate pack along with the non-welded design creates minimal stress build up. The differential expansion problems typical of certain shell and tube designs are considerably lower in these units.

The relatively small length of the block in the cross flow direction, coupled with the open channels, make inspection and cleaning of both sides easy.

OCAP exchangers require 30 to 40% less volume than a traditional shell and tube unit, because there is no wasted space in the parallel plate design. The unit is constructed of modules that are easier to lift and install.

The OCAP units offer the designer greater flexibility to select options for arranging the blocks to fit a particular installation. These units are fully shop fabricated, maintaining consistent quality control.

The OCAP modular unit can be readily expanded with parallel units decreasing pressure drop and increasing heat duty as required for capacity increase projects.

MECS supplies key products to ensure successful plant performance and operation. MECS commitment to continuous quality, innovation in design, reliability, material development, value, and selection is always at the forefront.