Side-entry mixers. It’s what we do.

When storing crude oil, accumulated sludge can become very problematic. In most cases, this crude oil will ultimately settle at the bottom of a tank and solidify, making extraction very difficult. For this reason, it is important to engage in proper mixing techniques with a side-entry mixer.

Sludge is composed of both organic and inorganic materials that are derived from many different forms. This component of crude oil is much heavier than crude oil and will ultimately settle at the bottom of a storage tank. By utilizing a side-entry mixer, sludge will be less likely to accumulate and harden, removing the need for most manual cleaning procedures.

B.S. & W Management / Cleaning

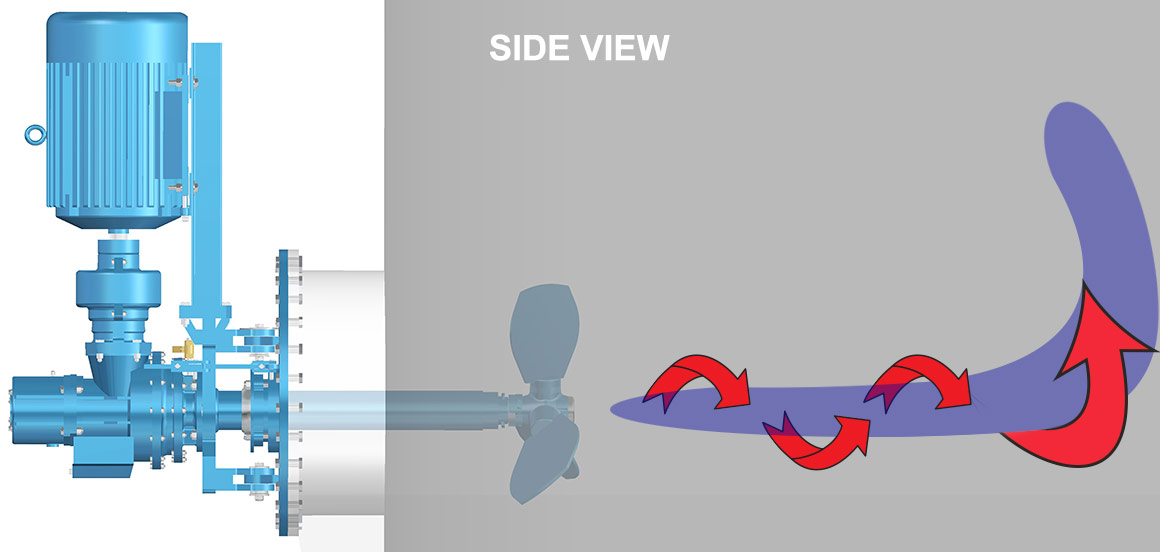

Side entry mixers are propeller-based mixers that are mounted near the bottom of a tank horizontally. These tank mixers create a spiraling circulation pattern to effectively deter the settling of sediment that may occur. To provide the best service, mixers are designed to suspend oil on the opposite wall of the tank.

Jensen Mixers has been a premier side-entry mixer manufacturer for over 67 years. We have made many valuable contributions to the side-entry mixer manufacturing industry during this time, including pioneering the Vari Angle mixer. This technology is often referred to as the swivel-angle design today.

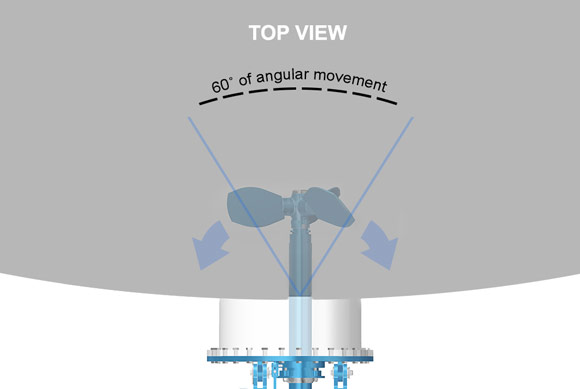

Suspension can easily be achieved with Jensen’s Vari Angle feature to help remove sediment that may build up in storage tanks over time. With the Vari Angle feature, a ball-type hinge allows 60° angular movement to cover a larger surface area at the bottom of the storage tank. These angle changes can easily be implemented by a single maintenance worker or automatically adjusted utilizing an option Mechanical Actuator.

Depending on the size of the storage tank, multiple side entry mixers may need to be utilized for adequate results. Mixers can either be installed in a cluster formation or a distributed formation. No matter what configuration is used, adequate power must be supplied to the tank.

Blending

Side entry agitators can also be used on storage tanks to adequately blend petroleum products for both refiners and traders. The blending process is much more complicated than mixing a simple group of components. Batch blending in storage tanks can help ensure the finished product contains adequate amounts of each individual components and a well-blended finished product.

Side entry mixers for storage tanks can continually blend your desired components for a uniform finished product. This happens by promoting circulation and agitation created by the circular operation of a propeller. By encouraging spiral circulation patterns, the individual components are more likely to blend together.

Much like with B. S. & W. management, not only will a blend be achieved, the tank will remain clean from sediment or sludge that develops throughout the process. Side entry mixers can remove the need for manual storage tank cleaning procedures after the tank has been pumped. This is due to the agitation that can be achieved to prevent settling and solidification of components within the storage tank, namely sludge.